SCHNEEBERGER NEWS

The latest trends from the world of 5-axis CNC grinding

New features of the CAD/CAM software Qg1, further machine development, customer reports and background information. All of that, only in SCHNEEBERGER NEWS.

Live from CCMT Shanghai: Skiving Cutter Profiling, Shank Tool Grinding and more…

The Chinese tool grinding market has played a major role in SCHNEEBERGERs company history for over two decades. Firmly established with its own branch in Nanjing in 2005, with ten participations at CIMT Beijing and now with its first attendance at CCMT Shanghai, the twelve-strong sales and service team proves once again its firm foothold in the Chinese market.

Read moreEconomical Regrinding of Large Tools with the Aries NGP+ from SCHNEEBERGER

There is no way around the Aries NGP+ when sharpening woodworking tools: Planing tools, finger joints, shank tools and profiling tools up to Ø 410 mm, as shown in the video.

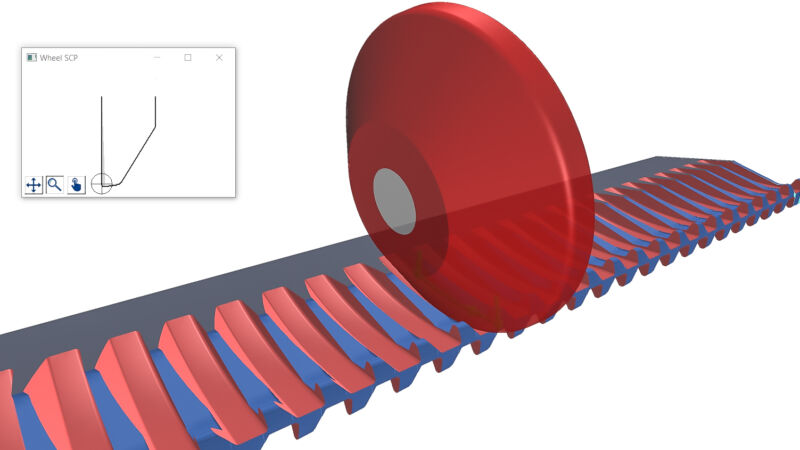

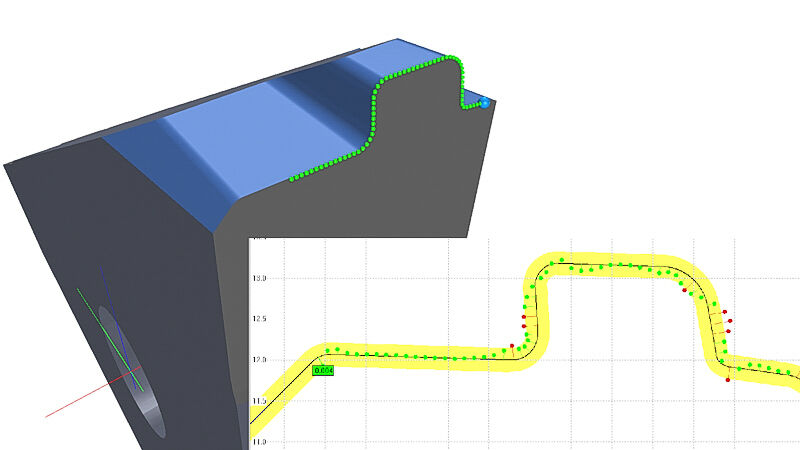

Read moreFresh & Sharp in Quinto Qg1, release 2024-02

Latest version of SCHNEEBERGER CAD/CAM software Qg1: New features for a wide range of applications and currently 1009 TOOGLE sample tools.

Read moreIn future, even more customers will be able to call a SCHNEEBERGER grinding machine their own. A new assembly plant makes this possible

Assembly of the Norma NGC is relocated to the company's own plant in Costermano, Italy. It follows its smaller sister, the Aries NGP, which has already been produced in the northern Italian manufacturing belt for 5 years.

Read moreReliable Manufacturing of Wire-Bonding Tools

Tools for the electronics and semiconductor industry, reliably ground on the fully automated SCHNEEBERGER 5-axis grinding machine ARIES NGP SCARA.

Read moreHappy Holidays

For all the excellent teamwork and your confidence, we want to sincerely thank you. We are looking forward to many more exciting projects in the coming years. Your SCHNEEBERGER team wishes for a successful 2024.

Read moreFresh & Sharp in Quinto Qg1, release 2023-11

Latest version of SCHNEEBERGER CAD/CAM software Qg1: New features for a wide range of applications and currently 1003 TOOGLE sample tools.

Read more100 years of SCHNEEBERGER - the Big Celebration, on Land and Sea. Part 3: After-Party

Team SCHNEEBERGER can celebrate. Until late at night, with loud music, green SCHNEEBERGER cocktail, in the mist of colorful lighting. The party scene transforms the company into a nightclub in a class of its own.

Read more